Sodium Alginate BioPlastic Trials

For this series of homemade bioplastic, I started with the following recipe from Sodium Alginate. Each trial has its own unique variations in recipe, process and as a dried material.

Recipe for Sodium Alginate BioPlastic:

10g Sodium Alginate [Dissolved in 55mL Distilled Water]

30g Glycerin

10g Olive or Sunflower Oil and a few drops Essential Oils

370mL Distilled Water

Whisk for a long time until mixture is like smooth putty

1:10 Ratio of Calcium Carbonate: Distilled Water in a spray bottle

Calcium Carbonate solution reacts with the Sodium Alginate mixture to form a protective membrane. Spray underneath and on top of bioplastic sheet. Let dry and then wipe down with water. The material becomes more brittle with more time in the Calcium Carbonate solution.

FORESTMy fourth sheet of Sodium Alginate bioplastic. Both Forest and Ocean survived a test of durability when I brought them into a snow storm! There are a few tiny holes where the material is not reinforced with the cotton fiber, and the color rinsed out of the raw cotton. The material and silk fabric held both shape and color well though in the snow.

The texture is dry in comparison to the Ocean piece. May be due to the clumpy and uneven distribution of cotton or just too much of it. I wonder other ways I can reinforce the strength of the waterproof material.

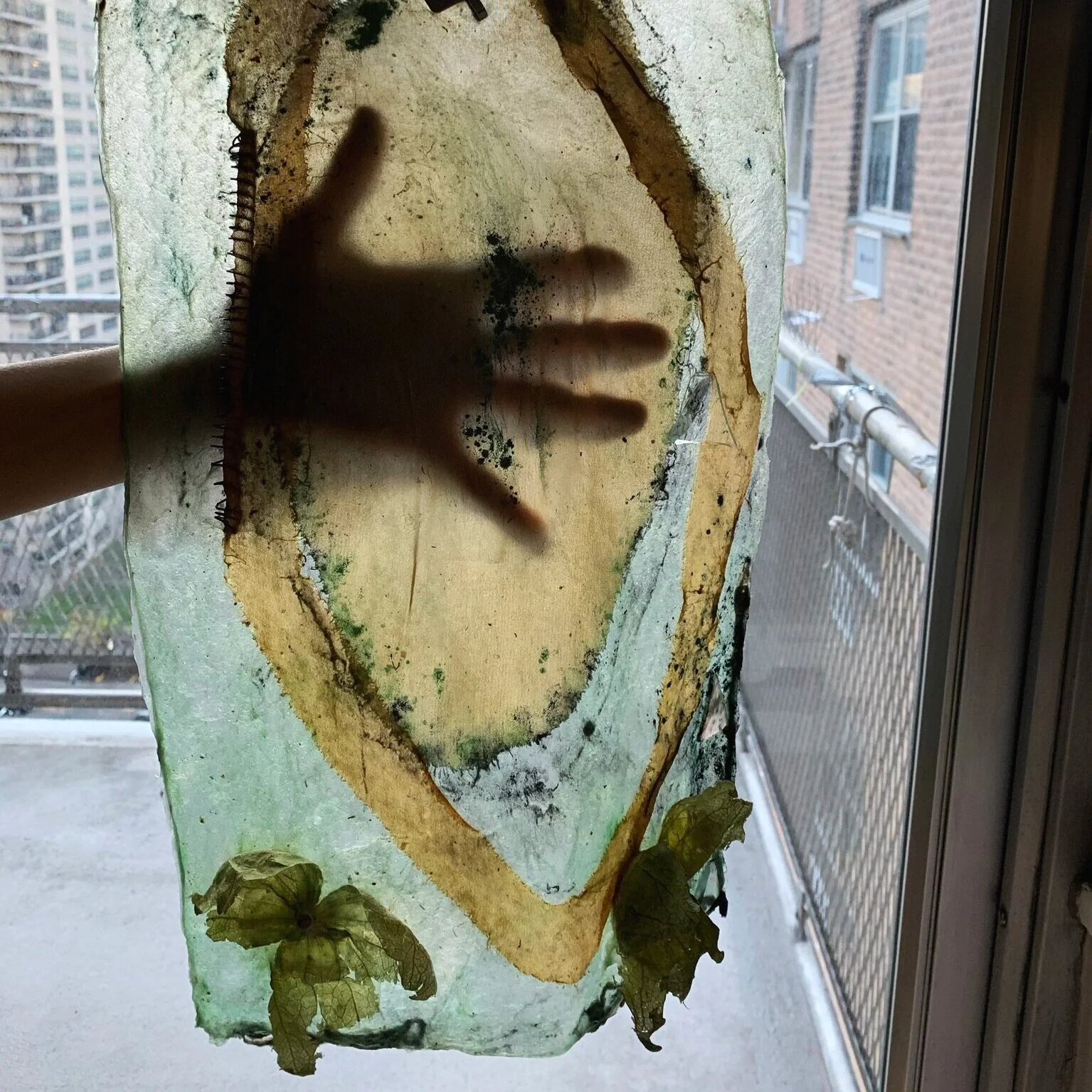

OCEANThe second trial in my series of full sheet sodium alginate bioplastic creations and the most successful result so far.

Color and overall appearance - it’s shiny and pretty okay!

Texture - soft, smooth and bendy

Durability and impermeability similar to a thin rubber

Held shape and size with little shriveling while drying

Placement of objects creates depth perception

Hypothesis why I had these good results:

Recipe ratio of extra olive oil and / or glycerin to less sodium alginate

Less calcium chloride while drying

Little fidgeting and movement to spread out the mixture after pouring into the door mold.

Not too much “stuff” on top and very gentle with the mica powder

Plenty of pulled cotton in the mixture, mostly evenly distributed, and with no other stiffening additives (like egg shells, which may create a more paper-like consistency)

Patience while drying!

SWAMPThe third iteration.

Sunflower oil instead of olive oil

Used eggs shells and pulled cotton in the mixture

Threw a whole bunch of “stuff” on top

Tried to dry quickly and did not wipe down diligently after drying

More paper-like consistency

Too much mica powder created a mucky matte color

However, very durable and water proof and resembling leather - I was dragging it around in the snow!

Would like to iterate for a material similar to leather that may try to make into a bag or backpack

Curious to try another where one section has egg shells to see if there’s a difference in consistency - I do think they look cool!

ATTICThe first full-sheet trial that I created with this recipe. It is an ugly one! I had in mind an unfinished attic with the pink and yellow foam fluff distributed like a maze throughout the attic floor. I remember as a child I was warned not to step on it otherwise I would fall through! A fear that always stuck with me.

Shredded cotton the mixture came out like little pellets

Cotton thrown on top and died with yellow onion skins created a very strange and freaky result.

Shrunk more than the others with a thicker and more brittle texture, possible due to shredded vs. pulled cotton, amount of Calcium Carbonate solution, and the madder powder used as color dye

Also possibly less glycerin and oil in the mixture with a higher ratio of Sodium Alginate

It is very durable and water-proof though! A theme throughout all trials.